RIDA BRAND

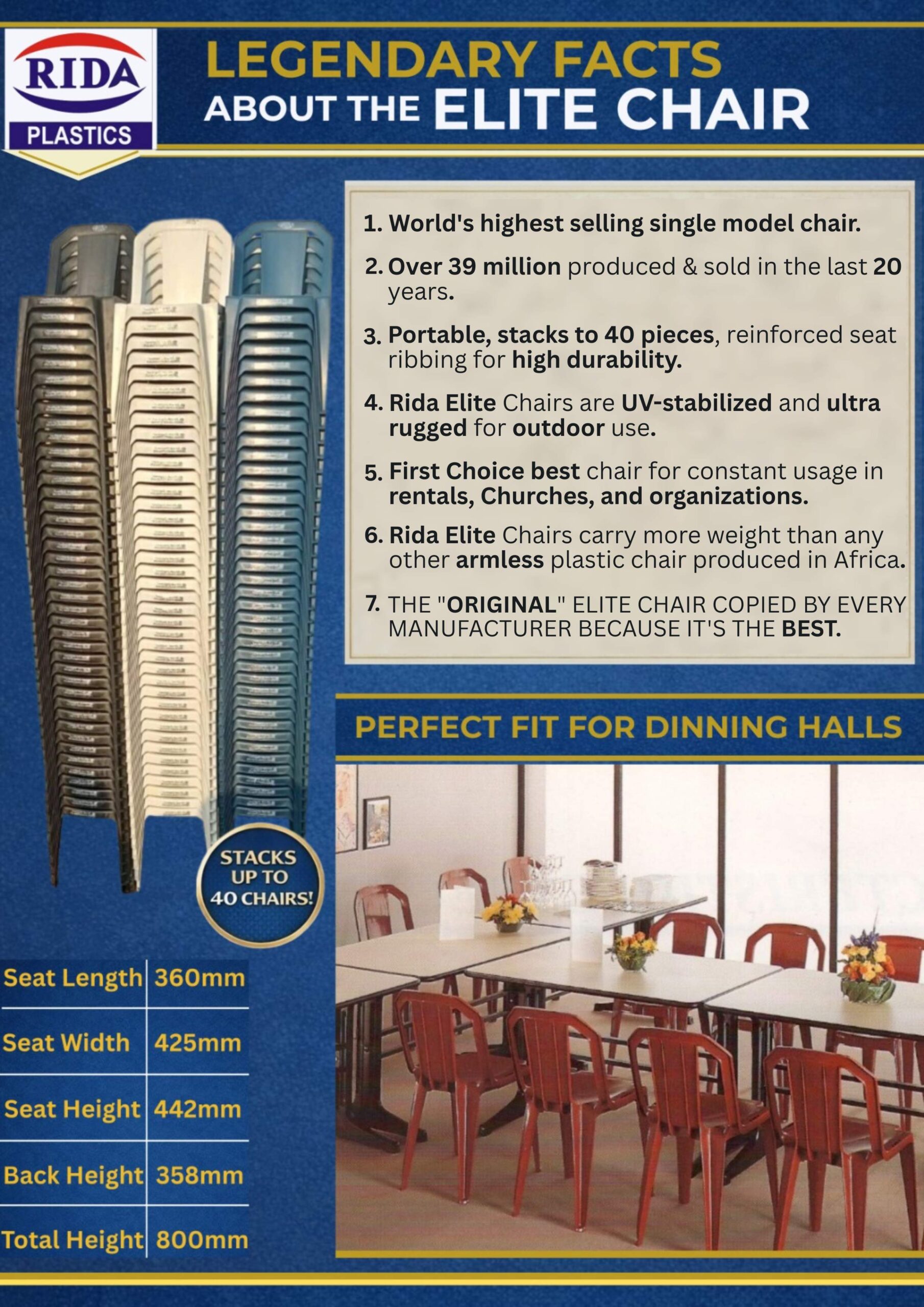

The RIDA BRAND is well known throughout Nigeria since the1960's and is synonymous with quality, integrity and strength. As a household name, three entire generations are familiar with our "made in Nigeria" products. Over 18 million of our chairs have been sold all over Nigeria and West Africa.

Rida National Plastics is a pioneer in the plastic recycling field since 1996. We recycle over 1000 tons of waste plastic material per month to produce quality post consumer goods. In this plastic production, we reprocess degenerated waste plastic materials, sourced from all over the country that we blend with Virgin content raw materials and produce excellent finished, thereby becoming a 'veritable agent' helping in the clean environment campaign. We are among the most environmental minded manufacturing organisations in Africa with possibly the cleanest carbon footprint.

Commercial Quality & Standards

+12,000 tons per year

BOD & +300 Employees

Seating +18M since 1960

TEAM

H. AGHA

Z. AGHA

W. AGHA

F. OWODUNNI

C. Mantri

G. Flayih

A. Akinola

C. Anil

J. Amit

E. Jad

O. Adeyinka

O. Alakabani

B. Malvis

E. Omwirhiren

G. Abasiubong

S. ADETUNDE

J. Umoh

T. Akinyeye

K. AINA

Here's what our Customers are saying:

DIVISIONS

We have started our in-group Beverage plant under the name of Real Drinks Company and are currently producing Refresh Fruit flavoured Beverages and Recharge Energy drink in our unique inhouse invented bottle shaped flexible packaging called SMARTPACK (that which we have global design protection). Our SMARTPACK weights ¼ of a PET bottle and takes up 1/50th of the disposal space in the waste stream, reducing the carbon foot print CO2 emissions on the dump trucks taking waste to the landfills, while taking up far lower space in the dump sites (compared with PET bottles). https://realdrinks.com, https://www.facebook.com/realdrinksng

In 2021 The Federal government of Nigeria joined the African Circular Economy Alliance headed by the United Nations and World Economic Forum and introduced new regulation via the National Policy on Plastic Waste Management specifically the Extended Producer Responsibility: to compel the packaging manufacturers to use recycled waste plastic content in their new packaging and reduce the burden of their brands waste plastic pollution impact on the environment. However, for the packaging remanufactures to adhere to these policies and use recycled plastic content, a sustainable supply chain of recycled plastic raw materials (from waste plastic) must be created.

We have set up a new Plastic Waste sorting, processing and recycling plant to sort waste plastic HDPE Blow bottles, containers and jerry cans to produce 5,000 tons of rHDPE resin per annum for onward supply to the established blow moulding plastics converters in Nigeria who supply various industries with this packaging requirements.

We are in the process to establish a new 30,000 tons per annum recycling plant unit to recycling waste plastic PET bottles and supply food grade recycled PET flakes to the next link in the drinks and beverage supply chain,.

This will provide a strategic opportunity for the major brand plastic polluters in Nigeria to reintegrate their waste plastics packaging back into their local manufactured packaging (to close the loop) in line with their extended producers responsibilities and reduce their foreign exchange import dependence on virgin resin.