Manufacturers of uPVC PIPE’S

BENEFITS OF uPVC PIPES

Lightweight & Cost-Effective

uPVC pipes are remarkably lightweight—only 1/6th the weight of steel pipes and 2/3rds that of cement pipes. This makes them easy to handle, transport, and install, significantly reducing labor and logistics costs.

Excellent Corrosion Resistance

As a non-metallic material, uPVC is immune to all forms of metallic corrosion. It withstands aggressive environments, including high-sulphate soils and chemically active zones, without degradation.

Smooth Internal Surface

uPVC pipes maintain long-term internal smoothness, ensuring superior hydraulic flow. This minimizes friction losses and prevents scale build-up and internal abrasion over time.

High Chemical Resistance

uPVC is resistant to a wide range of chemicals, including acids, alkalis, salts, and industrial effluents. It performs well in both residential and industrial applications, and is inert to saline water, alcohol, detergents, and aliphatic hydrocarbons.

Easy & Quick Installation

Installation is simple and efficient, requiring less time and effort compared to cast iron or cement pipes. Leakproof joints using rubber ring seals reduce maintenance costs and enhance system reliability.

Long-Term Durability

uPVC offers excellent impact strength and structural rigidity, making it suitable for underground applications. It withstands both soil pressure and vehicle load and is immune to damage from insects or rodents.

UV & Weather Tolerance

Designed primarily for underground and indoor use, uPVC pipes can also be stored outdoors for short periods without deterioration, thanks to their resistance to solar radiation.

Safe for Potable Water

uPVC pipes are non-toxic, tasteless, and odorless, making them ideal for conveying drinking water. They do not alter the quality or taste of the water transported through them.

Fire-Resistant

The uPVC compound used in our pipes is self-extinguishing and does not support combustion. Once an external flame is removed, the material ceases to burn—making it a safer option in fire-prone environments.

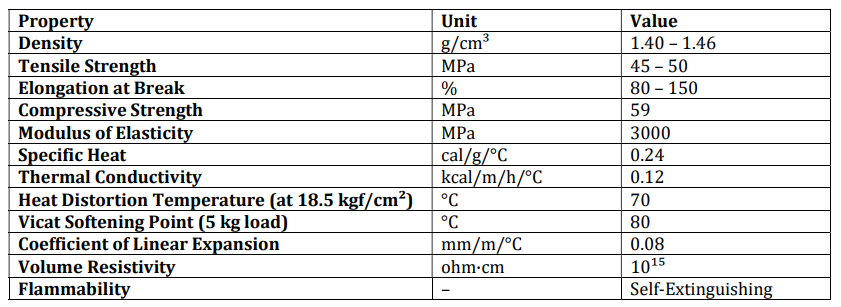

GENERAL PROPERTIES OF uPVC

uPVC (Unplasticized Polyvinyl Chloride) is a rigid thermoplastic material widely used in piping systems for water, drainage, electrical, and industrial applications. As a thermoplastic, its physical properties may vary with temperature, so understanding these characteristics is essential for proper system design and performance evaluation.

The table below outlines the key physical, thermal, and mechanical properties of uPVC under standard conditions. Note that pressure ratings and material behaviour can change with temperature, and appropriate derating must be applied in high-heat environments.

RANGE OF PRODUCTS

- Pressure Pipes

- Drainpipes

- Cable Ducting and Conduit Pipes

- Riser Min Pipes with SS coupler

- Borehole Casing/ Screen Pipes

- Rubber Ring Gasket for Drain and Pressure Pipes

PRESSURE, DRAIN & CONDUIT PIPES

At Rida National Plastics Ltd, we manufacture one of the most extensive ranges of pressure pipes, drainage pipes, and electrical conduits, fully compliant with DIN, ISO, EN, and BSI dimensional and performance standards.

Each pipe undergoes rigorous quality control and testing to ensure it meets all required specifications for durability, safety, and structural integrity. We strictly adhere to international standards, and every product is subjected to comprehensive physical, mechanical, and chemical tests, including:

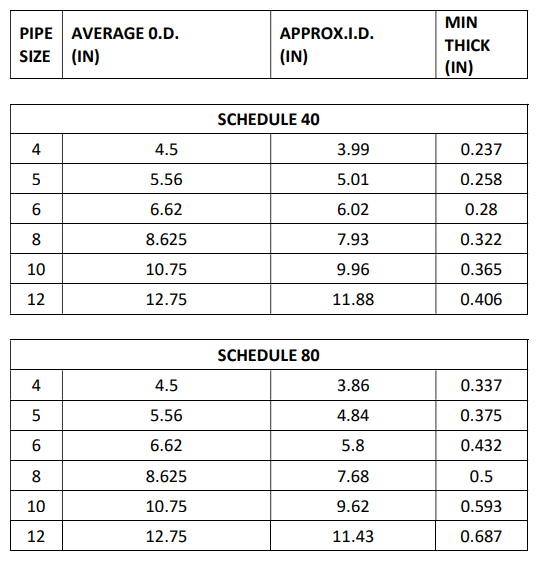

Dimensional Accuracy

- Pipe Length

- Outer Diameter

- Wall Thickness & Uniformity

- Chamfered Edges

- Internal Bore Uniformity

- Socket Internal Diameter & Length

- Socket-to-Pipe Axis Alignment

Performance & Material Tests

- Heat Reversion Test

- Acetone Resistance Test

- Sulphuric Acid Resistance Test

- Impact Strength Test at 27°C

- Impact Strength Test at 0°C

- Short-Term Hydrostatic Pressure Test

- Long-Term Hydrostatic Pressure Test

- Flattening Test

These tests are essential to verify that our pipes are not only dimensionally accurate but also chemically stable and mechanically reliable under demanding conditions.

Our state-of-the-art laboratory in Lagos is fully equipped with special-purpose testing equipment and jigs, enabling us to consistently perform and validate all the above tests in-house, guaranteeing that each pipe meets or exceeds the required national and international quality standards.

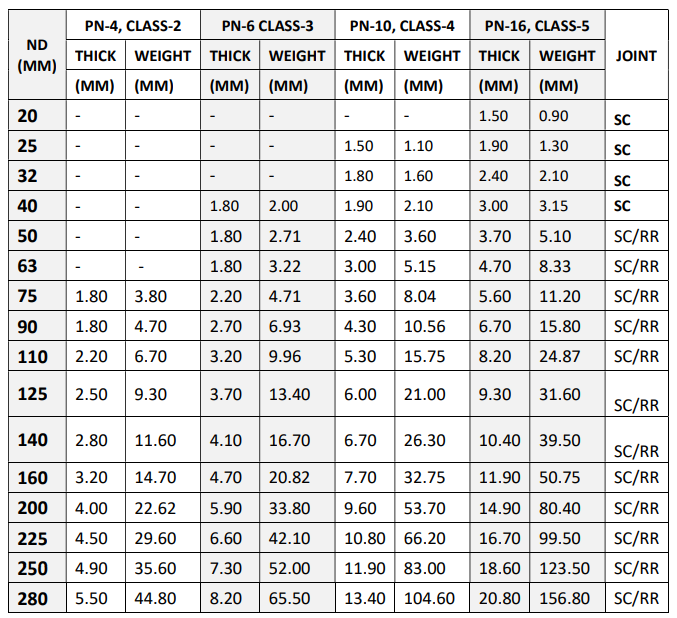

PRESSURE PIPE DIN8062

- SC: Solvent cement socket Joint

- RR: Rubber Ring Socket Joint

- Colour: Grey or Black

- Length: 6 meters as per standard

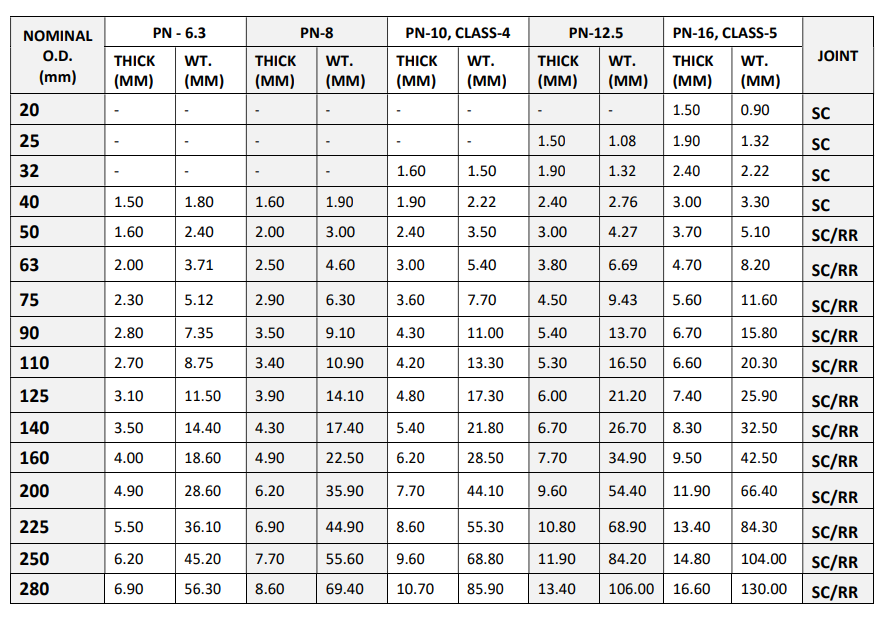

PRESSURE PIPE EN/ISO 1452

- SC: Solvent cement socket Joint

- RR: Rubber Ring Socket Joint

- Colour: Grey or Black

- Length: 6 meters as per standard

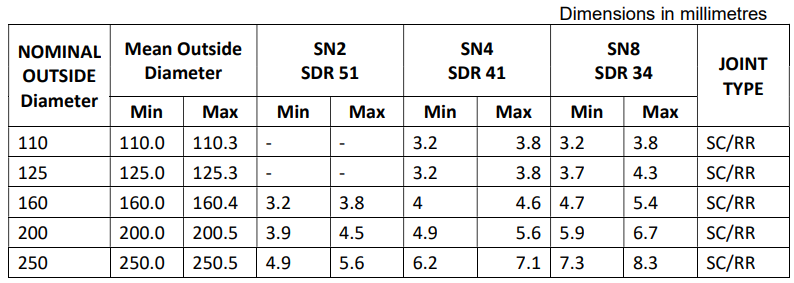

PLASTIC PIPING SYSTEMS FOR NON-PRESSURE

UNDERGROUND DRAINAGE BS EN 1401-1:2009

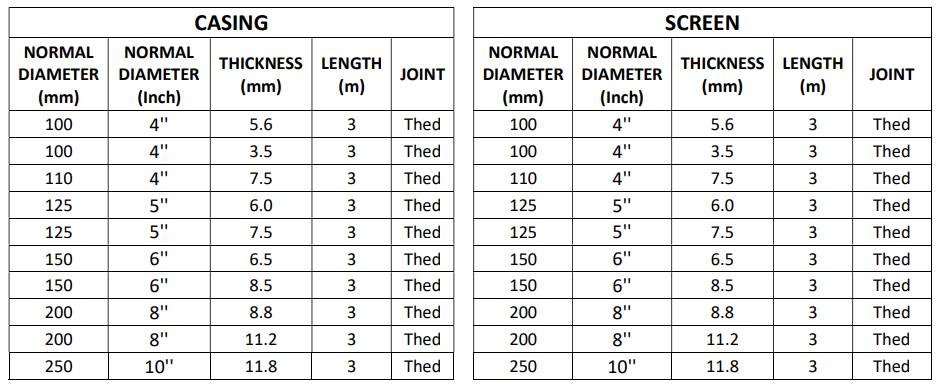

CASING & SCREEN PIPES (DIN 4925 STANDARD)

At Rida National Plastics Ltd, we manufacture high-quality casing and screen pipes in full compliance with DIN 4925 specifications, suitable for borehole and groundwater extraction systems.

Our casing pipes are produced in diameter sizes 113 mm, 125 mm, 160 mm, and 225 mm, and are colored blue in accordance with international standards for water well applications.

We ensure precise dimensional control through the use of advanced production technology, including:

- Trapezoidal threading in Bell and Flush jointing systems, strictly manufactured to DIN standards

- Computer-controlled threading machines for accurate cuts, consistent dimensions, and full interchangeability of joints

Poor-quality threads are a common cause of casing failure due to inadequate overlap and misalignment. At Rida, our threading process guarantees:

- Secure and reliable joint connections

- Maximum overlap for enhanced strength

- Smooth and leak-free assembly with consistent interchangeability across all pipe sections

Our casing and screen pipes are subjected to the same rigorous quality tests applied to our pressure pipe range, including hydrostatic, impact, chemical, and dimensional testing.

These products have been tested, approved, and used by UNICEF in their borehole drilling programs, a testament to their durability, precision, and international-grade quality.

WELL CASING (ASTM F 480 STANDARD)

At Rida National Plastics Ltd, we manufacture high-performance well casing pipes and couplings in full compliance with the ASTM F 480 specification, designed for water wells and groundwater monitoring systems.

This standard applies to thermoplastic materials produced in:

- Standard Dimension Ratios (SDR)

- Schedule 40 (SCH 40)

- Schedule 80 (SCH 80)

Our casing systems are engineered for use in both domestic and industrial boreholes, as well as environmental and groundwater monitoring wells.

Key features include:

- Flush-threaded joint systems for both screen and casing pipes, ensuring tight, secure, and leak-proof assembly

- Superior thread integrity and alignment, minimizing the risk of failure during or after installation

- High resistance to chemical corrosion, abrasion, and mechanical stress, making them ideal for long-term underground applications

These casings offer a reliable, durable solution for water well construction, combining ease of installation with compliance to international monitoring and drilling standards.

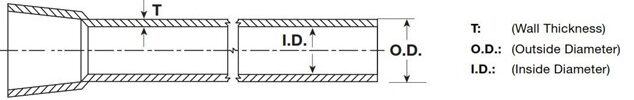

RUBBER RING GASKETS

At Rida National Plastics Ltd, we manufacture high-quality rubber ring gaskets specifically designed for drainage and pressure pipe jointing applications.

Our gaskets are produced using Nitrile rubber (NBR), a material known for its exceptional resistance to oil, fuel, chemicals, and pressure, ensuring long-term sealing performance in both underground and exposed environments.

Key features:

- Engineered to conform strictly to international design standards and specifications

- Ensure leak-proof, flexible, and durable joints across a wide range of applications

- Subjected to comprehensive quality testing for dimensional accuracy, elasticity, and chemical resistance

These gaskets play a critical role in ensuring secure, long-lasting connections between pipe sections, minimizing the risk of leaks and enhancing system reliability under varying operating conditions.

| Forsheda 576 Anger-Lock™ Seal

Application Design & Function By integrating the seal into the pipe, it eliminates issues found with loose gaskets and ensures proper alignment. The seal also accommodates minor groove variations, delivering consistent, leak-free performance. |

Seal Performance & Quality The Forsheda F-576 Anger-Lock™ seal is engineered to meet or exceed European standards for pressure, vacuum, deflection, and shear loads. Its low assembly force design ensures easy and secure jointing. |