Closed-Loop Plastic Manufacturing Operations

RIDA NATIONAL PLASTICS is the leader in Waste Plastic Recycling and Closed-Loop Plastic Manufacturing. Our 25-year sustainable operation is a system where waste plastic is collected, recycled, reprocessed, and reused to manufacture high-quality plastic products indefinitely.

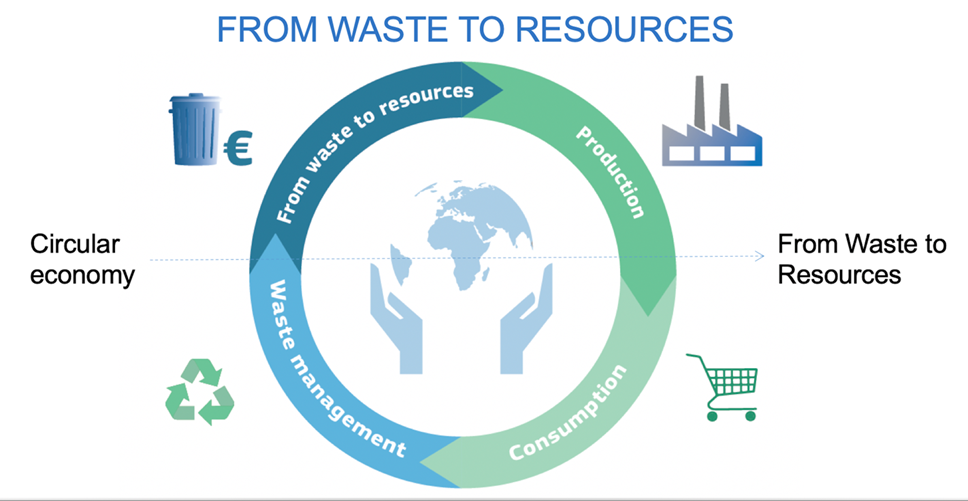

This model represents a circular economy by continuously recycling materials, preventing landfill waste, and reducing reliance on virgin plastics.

Key Components of Our Closed-Loop System

- Collection: Gathering plastic waste from consumers or industrial processes.

- Recycling: Waste plastic is sorted, shredded, ground, and washed into recycled plastic chips (regrind).

- Reprocessing: Recycled plastic chips (regrind) are extruded and converted into high-grade raw materials (pellets or granules).

- Manufacturing: Reprocessed recycled raw materials are used to create new plastic products, forming a continuous loop.

- Purchasing: Consumers and industries buy recycled-content products, completing the loop and driving further recycling.